As part of the The Dewatering Institute‘s commitment towards knowledge sharing, TDI is developing a series of monthly interviews of industry leaders and professionals from different parts of the world. This months edition features David Wright. He is a Chartered Geologist and Managing Director of UK based Stuart Wells Limited with 30 years experience in the design and operation of dewatering projects.

Can you tell us more about your work history and how you go where you are today?

I first got interested in groundwater at University in the early 90’s and managed to get a job as an Engineer at Stuart Wells. Was under the tutelage and general bag handler for the technical lead, Jim Pontin and was involved in some nice dewatering projects such as Hong Kong Airport and the first high speed rail link in the UK. Did a lot of site work and project supervisor, which was where I learnt and got a good board education in groundwater control.

Subsequently went off to form a new dewatering company, Project Dewatering with Dave Gowans (Drilcorp) and the late Professor Paul Younger. After 15 years of that, went back to run Stuart Wells and I’ve enjoyed every minute of it. We have been involved in a lot of the UK major infrastructure projects such as Hinkley Pont C, Crossrail and HS2 as well as doing the more ‘bread and butter’ manhole job in rural Yorkshire. The lessons learnt from all my previous experiences in the industry has helped me build and manage a dewatering team I am immensely proud of.

What is the biggest challenge you’ve seen in the industry?

It has to be the environment and how the industry reacts. On the whole I feel dewatering is a relatively environmentally friendly industry. We are dealing with a natural resource on a daily basis, we can clean up most contaminated groundwater we come across. It is an effective measure to control groundwater flow in construction and a ‘green’ alternative to our competitors in the piling industry who are using steel and concrete and the ground stabilisation industry injecting chemicals into the ground, as a means of cutting-off groundwater flow. As an industry, I see our response to environmental issues in two parts, carbon, and groundwater as a natural resource.

With Carbon, unfortunately we seem to be on a plateau at the moment. As a company we have concentrated on lowering our carbon output, by reducing fuel usage on an operating dewatering pumping system. We have invested and use very fuel-efficient pumps; we use biofuels where possible and variable speed drive pump control panels to reduce hertz and power requirements. I hear a lot about carbon reduction technology not being here at the moment, and there is some truth to that. We have looked at running pumps off solar power with battery backup, but the power generation limits this to low yield pumping operations. We have looked at battery banks on generators, to limit the hours diesel generators are running to operate a 24/7 dewatering pumping system. But for most projects the power requirements result in impractical size and scale of battery support.

As mentioned before, as an industry we are using and rely on the natural groundwater resource. So its in our interest to respect and manage groundwater responsibly. In 2018 the UK dewatering essentially became a licensed industry, with UK Environmental Regulators setting permit requirements on both groundwater abstraction and discharge for Dewatering operations. There are differing conditions set out by regional agencies in England, Scotland, Wales, and Northern Ireland. We absolutely respect the objective to protect groundwater resources. They acknowledge dewatering as a legitimate activity, but the bottom line is the licensing exemption limits on flow and pumping periods are too low for the vast majority of dewatering projects.

The lessons learned from all my previous experiences in the industry has helped me build and manage a dewatering team I am immensely proud of.

The collective UK dewatering industry seemingly did not see this coming, and I still get frustrated by us not being at the table and lobbying more strongly, when compared to the other industries that abstract groundwater, such as mining. The frustration comes from the regulators not fully appreciating the peculiarity of the dewatering industry. From my experience there are two types of dewatering jobs. The planned ones, where dewatering requirements are foreseen, and any environmental conditions can be factored in. The others are the unplanned ones, with a phone call from a contractor who has encountered groundwater problems. The difficulty with the latter is more often than not it requires an immediate pumping and discharge response, sometimes to counter serious ground engineering risks. However, the timeframe which the regulators operate in, and the 1–4-month process of gaining permits, is just too long and impractical.

There are positives, the push towards recharging groundwater to ground has real benefits both in terms of the environment and additional revenue. In the UK after 4 years of trying to operate within the permitting constraints, there needs to be a period of reflection and review on how the environmental agencies responsible for the management of the groundwater resource and the dewatering industry can work together better. We both want the same things.

It is a lesson for the global dewatering industry as it is probable that similar imposed environmental controls may be coming your way in the future.

Can you tell us why TDI is important to the industry?

Dewatering is an integral component of the construction industry. Looking forward, with our expertise in managing and engineering groundwater resources. We potentially have a big role to play in the 21st century. We need to place ourselves and take the opportunity of growing as a partner in the construction industry, where its environmental impact will increasingly be scrutinised.

Dewatering people globally may communicate via social media and might have undertaken some joint ventures in the past. But it’s nice to have the opportunity to present ourselves collectively and professionally. I hope that one of the benefits of The Dewatering Institute is a platform where globally we can share developments, successes, and failures with a view to reducing carbon and promoting dewatering as an environmentally friendly industry.

What/where has been your favourite project so far and why?

I do not think it’s just me, when l say that you tend to remember the difficult jobs, with the ones that go swimmingly, fading in the memory. Two projects stick in the mind for me, that are at different ends of the scales.

One was a relatively straightforward vacuum wellpoint dewatering operation for a shallow pipeline with a handful of manholes in South Wales. The geology of South Wales will test anyone, it can range from very fine silty sands to sand & gravels with boulders as big as a car. On this project we had the lot with big variations over short distances. We had to adapt an observational approach and alter the installation method, design, and filter pack on what seemed like every wellpoint. But we got there in the end.

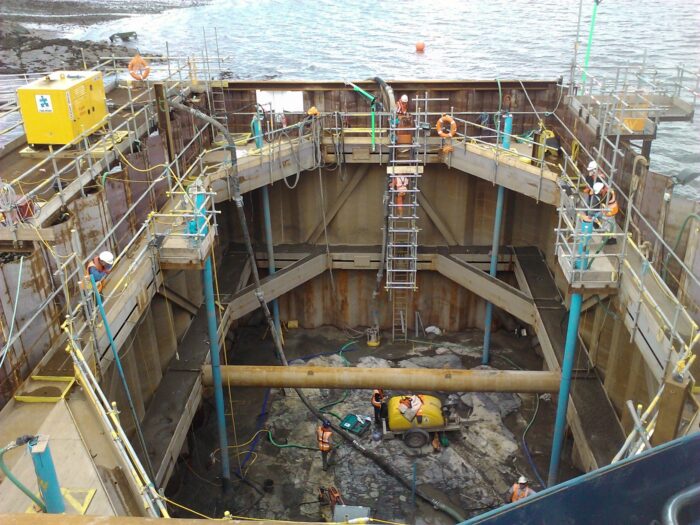

The second is Hinkley Point C which is a new nuclear power station in Somerset. It was a difficult project both technically and operationally with a tight programme. However, the satisfaction for me came from the ‘boring’ management side of dewatering. The required level of planning, health and safety, quality and environmental standards and the processes required, really pulled us up by the socks as a company and is something we have built on ever since.

The Dewatering Institute is a platform where globally we can share developments, successes, and failures with a view to reducing carbon and promoting dewatering as an environmentally friendly industry.

Why would you recommend younger generations a career in the dewatering industry?

There’s no doubt it is a really interesting industry to be in, as it crosses over so many other activities. There is the whole range of civil and construction projects with all the engineering involved. Environmentally you are dealing with water quality, ecology, and hydrology, with the whole thing centred around geology and hydrogeology. It’s definitely not boring and have seen many graduates using dewatering as a foundation to other career paths. However, there are some who fall in love with dewatering and stay, hopefully to be a force and play a part in the next generation and future of dewatering.

Hinkley Point C 2018

What has been the most inspiring thing someone has said to you within your line of work?

We are groundwater engineers and have to attempt to accurately calculate soil permeability values, to assess groundwater flow and dewater designs. Permeability is the widest ranging soil engineering parameters. Generally speaking dewatering sits within some five orders of magnitude. We can push consultants and the site investigation industry to undertake pumping tests and sieve analysis to help with permeability analysis. But as a very eminent hydrogeologist said to me once using a football analogy “its like trying to score a goal at Wembley (London) whilst shooting from St James Park (Newcastle)”.

As you have worked all over, what is your favorite place to work?

London, it just has everything.

Married to the job? A wellpoint guard of honour on my wedding day -1997

There are some who fall in love with dewatering and stay, hopefully to be a force and play a part in the next generation and future of dewatering.

What is your life motto/ words of wisdom to others in the industry?

Maybe not a single motto. But I am full of sayings, such as. Always buy good shoes and a good mattress….if you’re not in one you’re in the other”. My colleagues will vouch for the endless statements I make about dewatering, such as ‘the design should be one that enables you to sleep at night’ and ‘have a notebook and pen by your bed to write and off load any ideas and thoughts in your head’ and ‘we can stay in bed and lose money, why go through all this sweat and headache’. They all seem bed and sleep orientated, wondering what a psychiatrist would think of that.

To keep up to date with the latest industry news and our monthly interviews with industry professionals, subscribe to our newsletter and follow us on social media. Join the TDI community by becoming a member now!