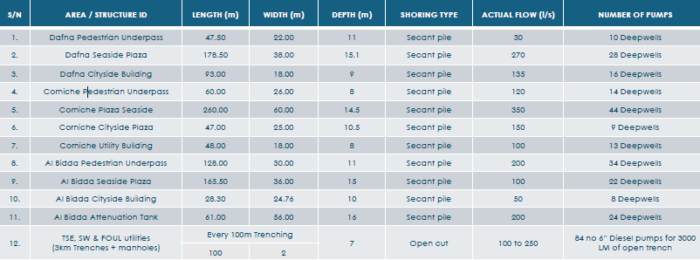

The Public Works Authority (PWA) and General Consultant (Parsons) were engaged to undertake the master planning and design of the Central Doha and Corniche Beautification (CDCB) Project. The CDCB project covers downtown Doha from Al Corniche Road to C-Ring Road. The project covers the institutional, government, and prestige developments between Al Corniche Road and A-Ring Road, and the commercial, residential, and business developments between A Ring Road and C-Ring Road. The scope of work includes the following: eleven structures and TSE, SW & FOUL utilities (3km trenching + manholes). The project is in Qatar, officially known as the State of Qatar, which is a small country situated in the Middle East, on a peninsula fringed by the Persian Gulf. The state of Qatar is situated on the Qatar Peninsula, bordered by the Persian Gulf, Saudi Arabia, and the United Arab Emirates.

Above: Corniche Pedestrian Underpass, Corniche Seaside Plaza, Corniche Cityside Plaza & Utility Building.

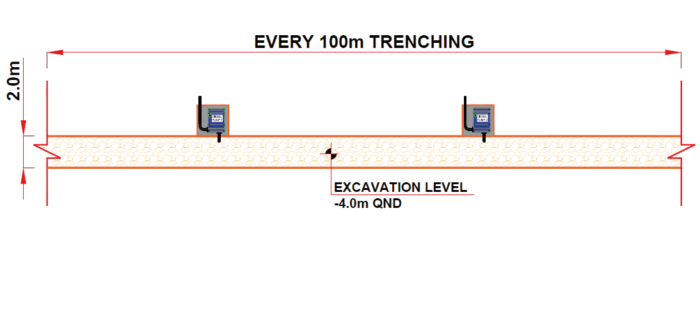

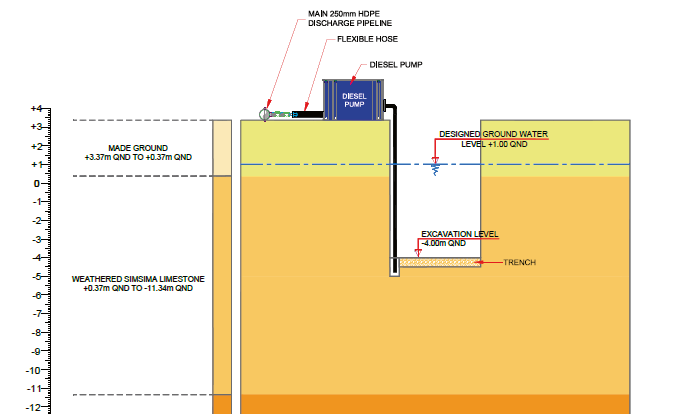

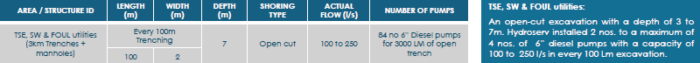

Above: TSE, SW & FOUL utilities (3km Trenches + manholes).

Project Challenges

The nature of the geology in the area, karstic limestone, and the close proximity of the sea as a source of recharge meant the system needed to be designed with flexibility to meet any unexpected inflows. Wherever we have an additional in-flow at the site, we installed additional electrical sump pumps to avoid flooding at the site.

Due to the site’s location, the only viable discharge options were direct discharge to the sea and to the stormwater network (manholes). As per QCS 2014, maintaining both the quantity and quality of the water within the permit parameters set by MOECC and PWA proved to be a significant challenge.

Unfortunately, due to space limitations on-site, there was no suitable area available for installing retention or settlement lagoons or ponds to manage high-turbidity water. To address this issue, we implemented our in-house designed lamella clarifiers to reduce turbidity. Additionally, we secured multiple discharge points within the site boundary to disperse the water more evenly across a larger area.

The sedimentation tank and clarifier are cleaned regularly to ensure optimal performance and maintain the efficiency of the dewatering system. The Corniche is one of the busiest routes in Qatar and it was a project requirement that it remain open during the entire works. The impact of this was:

• The Al Bidda Underpass and Tunneling works had to be completed in 3 phases to maintain the flow of traffic along the corniche. The dewatering system requires pipe welding works and to be operated fully over the entire tunnels even under the live road as it was diverted, and new phases were dewatered.

• Ministry headquarters, business towers and office buildings were located adjacent to this project site. These structures made access difficult making installations and monitoring works a daily challenge.

Project Summary

The following is a summary of the dewatering works for Central Doha & Corniche Beautification Package Initially, the main contractor wanted to excavate using an open-cut method. Hydroserv had experience with other projects in the vicinity of the site, as a result was aware of the variable ground conditions and identified that this would be a high risk to the project that would lead to project delays and cost escalation.

As part of Hydroserv’s value engineering and risk mitigation approach, it proposed conducting a pumping test in each

area to assess the effectiveness of the hydraulic barriers. Using the data generated it also performed a sensitivity analysis and numerical modeling. Although the scope was broad and many challenges were faced in this project, Hydroserv was able to successfully dewater the whole scope. There was a total flow of 1,750 l/s for the 11 nos. of structures and a total peak flow of 100 to 250 l/s for every 100Lm trenching works.Hydroserv installed a total of 222 nos. of deepwell pumps, 28 nos. of sump pumps, 84 nos. of diesel pumps, 42 nos. of generators, 8 nos. of lamella water clarifiers, 6 nos. of v-notch weir discharge tanks and 6,500 meters of HDPE pipes (range from 250mm Ø to 630mm Ø) during the course of this project.